6-8, allée du Val du Moulin - B.P. 69 - 93240 STAINS - FRANCE

Tél. : 33.1.48.26.62.12 - Fax : 33.1.48.22.37.15 - E-mail :

pouget.rail@wanadoo.frWeb : www.

pougetrail.comTese Specifications are given for your information only

and may be technically modified and improved.

RAIL WELDING EQUIPMENTS

Made in

4/6

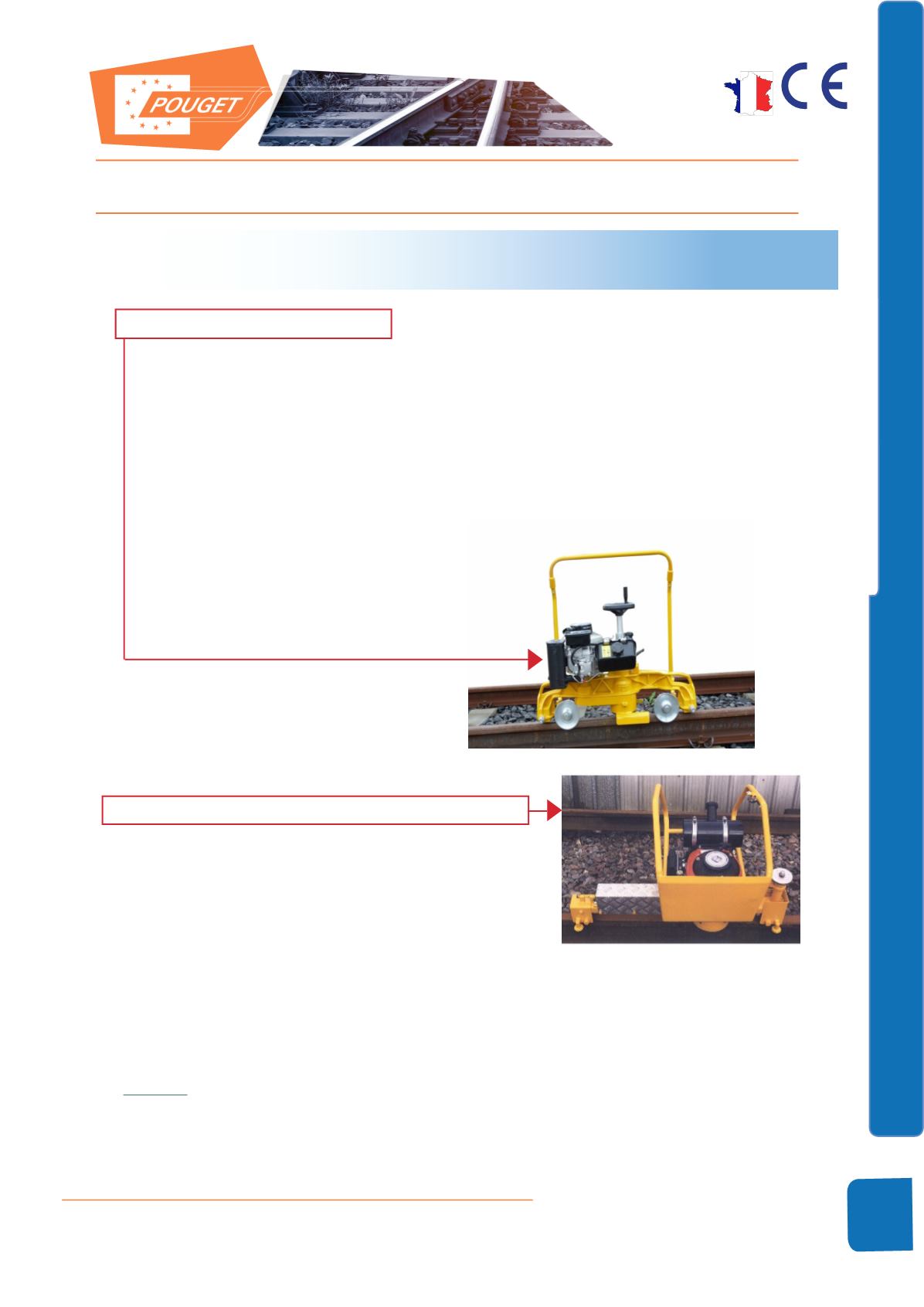

RAIL PROFILING GRINDERS

(

N-1

/

N-12

)

USE :

Grinding after Alumino-thermic welding of rails.

ADVANTAGES :

Grinding after Reprofiling of rails or Switches and Crossings.

N-1

PROFILE RAIL GRINDER

Portable, to grind the rail 100 RE-90 R - UIC-54 after aluminothermic welding

With BERNARD Petrol Engine 7 HP - 4-stroke

Inclination possible from the horizontal to vertical position

Total swiveling range of the grinding unit is more than 180°

Grinding Wheel Ø 150 mm x 75 mm - Ref. 1039-B

Special Frame Construction with full view of the grinding

Suface Light Weight System consisting of combined support

and guide rollers to hold the machine against the rail when grinding in horizontal

position

Rotating Speed of the Wheel : 4 000 rpm

Centre-to-centre Guide Runners : 1 m.

Grinding Accurate : ± 0.1 mm

Weight = 68 Kg

N-12

PROFILE RAIL GRINDER,

with Flexible

With Flexi-Horse, length 3.5 m equipped with :

▷

▷

Ø 150 mm CupWheel (option : 125 mm)

▷

▷

or Ø 150 or 200 mm Flat Wheel

This Machine is equipped with :

1 Petrol Engine 7HP (4 stroke or 2 stroke)

1 Flexi-Horse, length 3.50 m with Ø 150 mm Flat Wheel

1 Quick-Assembly Union between the Flexi-Horse and the Rail Grinding Machine.

Weights : Machine 58 Kg / Flexi-Horse 15 Kg

OPTION

with Electric Motor 4 kW - Ref.

N12-E

- Weight : 57 Kg