RAIL WELDING EQUIPMENTS

6-8, allée du Val du Moulin - B.P. 69 - 93240 STAINS - FRANCE

Tél. : 33.1.48.26.62.12 - Fax : 33.1.48.22.37.15 - E-mail :

pouget.rail@wanadoo.frWeb : www.

pougetrail.comTese Specifications are given for your information only

and may be technically modified and improved.

Made in

OPTIONS

Welding Square

- Tech. Spec. No.

2/6

7/6

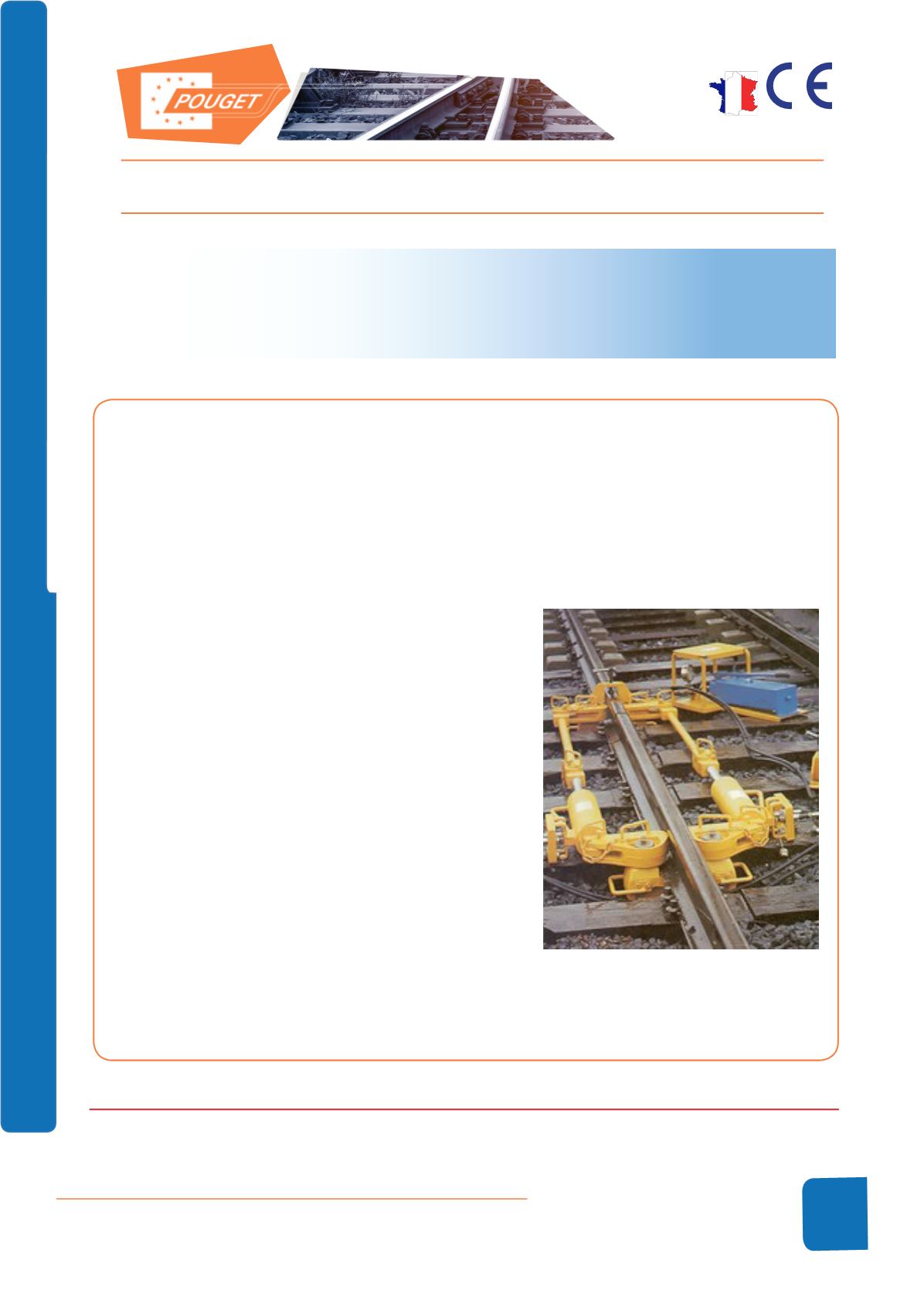

HYDRAULIC RAIL TIGHTENERS

-

TR-70

.

USE :

Adjusting the gap between 2 Rails before welding

Tighteners to free continuous Lengths of Rails.

ADVANTAGES :

Very Tough Equipment designed to ensure that trains can move freely, without

engaging the Track Gauge.

Tensile force =

700 KN

Longitudinal Stroke of Hydraulic Jacks = 350 mm

Operating Pressure = 600 Bars

Automatically operated Jaws suitable for all Rail Section up to 60 Kg/m.

Tie Rods of various lengths (to specify) ranging from 0.50 m to 2 m. (Standard Length = 1.80 m)

Overal Width : 750 mm (excl. tie rods)

Total Weight approx. = 270 Kg

Operates using a Manual Pump or Hydraulic Unit.

1

Standard Rail Tightener

ref.

TR-70

is equipped :

2 Tightening Sets by a Jaw

2 Hydraulic Jacks - Force 75 tons

2 Tighteners, Length 1.80 m

1 Manual Hydraulic Pump