6-8, allée du Val du Moulin - B.P. 69 - 93240 STAINS - FRANCE

Tél. : 33.1.48.26.62.12 - Fax : 33.1.48.22.37.15 - E-mail :

pouget.rail@wanadoo.frWeb :

www.pougetrail.comTese Specifications are given for your information only

and may be technically modified and improved.

MACHINES FOR TRACK WORK

Made in

USE

:

High Efficiency Complete Re-Profiling of the rail du rail. (Worn Rails, Rail Corrugation, etc. )

ADVANTAGES

:

This Automatic Unit gives a perfect quality and even results for grinding and re-profiling works on the rail :

Running Surface of the rails

Gauge-side of rails and Internal Radius of Head-Rails

ELECTRICAL RAIL REPROFILING UNITS

( For Rail Corrugation)

The

N-320

Modern Machine includes :

4 Ø 200 mm GrindingWheels

for the Running Surface of the rails (with Slant Setting).

(For Tramway Ø 100 mm Grinding Wheels).

2 Ø 150 mm

Grinding Wheels for the Gauge-Side of rails and Internal Radius of Head-Rails).

MAIN CHARACTERISTICS

Diesel Generator on Platform Trolley

Self propelled in 2 directions = 4/6 Km/H with Automatic Speed Variator.

Weight of the N-320 Machine without Generator = 1800 Kg / Weight of the Generator on the Platform Trolley = 2400 Kg

MINI GRINDER

= 4 x Ø 200 mm + 2 x Ø 150 mm

N-320

MEDIUM

GRINDER

= 8 x Ø 200 mm + 2 x Ø 150 mm

N-322

MAXI GRINDER

= 12 x Ø 200 mm + 2 x Ø 150 mm

N-323

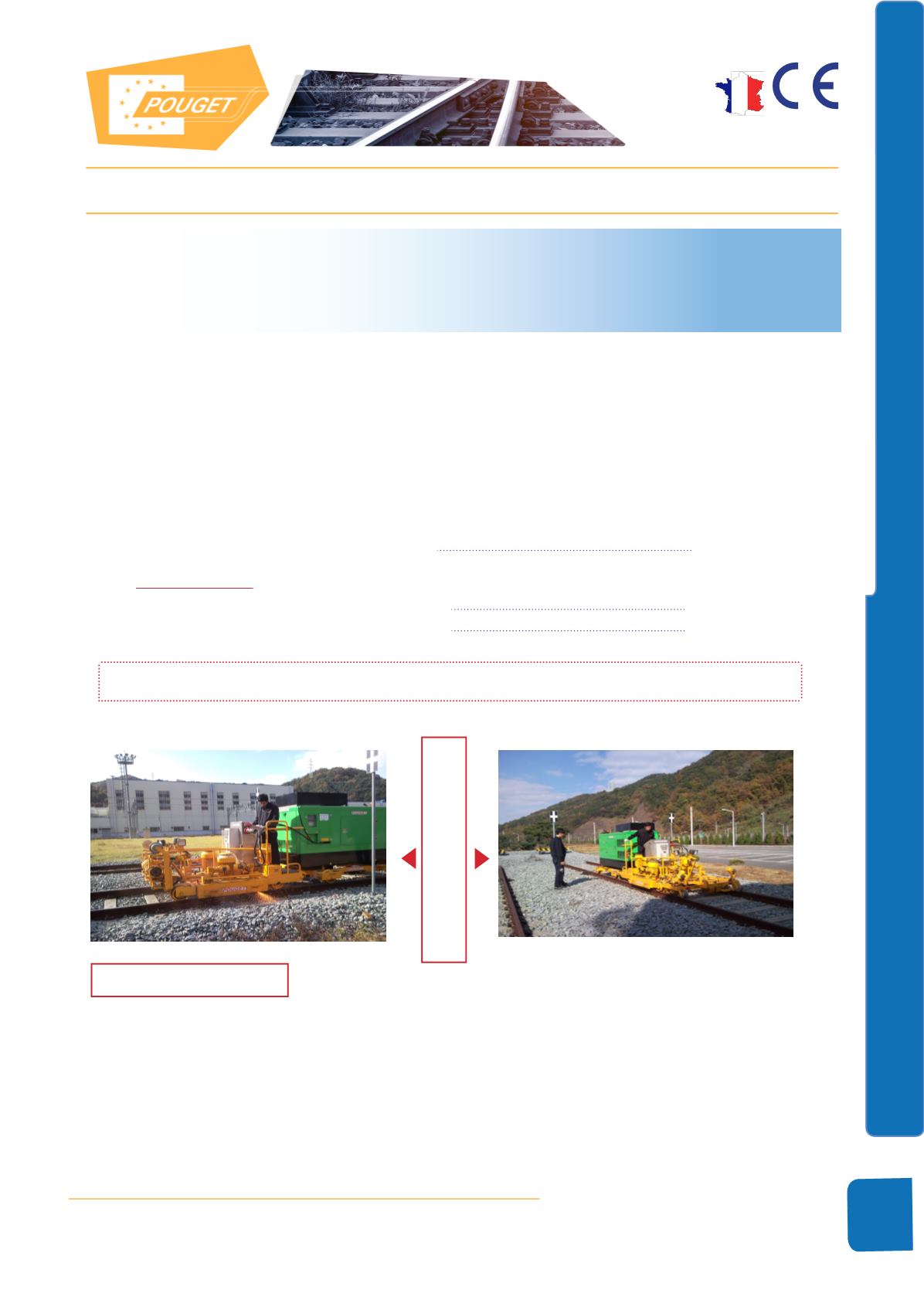

Re-profiling Unit Machine

N-320

working in South Korea

OPTIONAL EQUIPMENTS

SPARE PARTS (Tech. Spec. NO. 2/2) :

Lights for Operating during Night Works - Ref.

PE

Protector Cover the Operating Agent - Ref.

BP

Fire-Extinguisher - Ref.

EXT

TRAMWAY OPTION - Ref.

TR

▷

▷

Ø 200

mm Grinding Wheels - Ref.

1039-G

▷

▷

Ø 150

mm Grinding Wheels - Ref.

1039-A

Other Models :

See Page 1/1

for the Details of

the

Hydraulic Models

2/1