6-8, allée du Val du Moulin - B.P. 69 - 93240 STAINS - FRANCE

Tél. : 33.1.48.26.62.12 - Fax : 33.1.48.22.37.15 - E-mail :

pouget.rail@wanadoo.frWeb :

www.pougetrail.comMACHINES FOR TRACK WORK

Tese Specifications are given for your information only

and may be technically modified and improved.

Made in

7/1

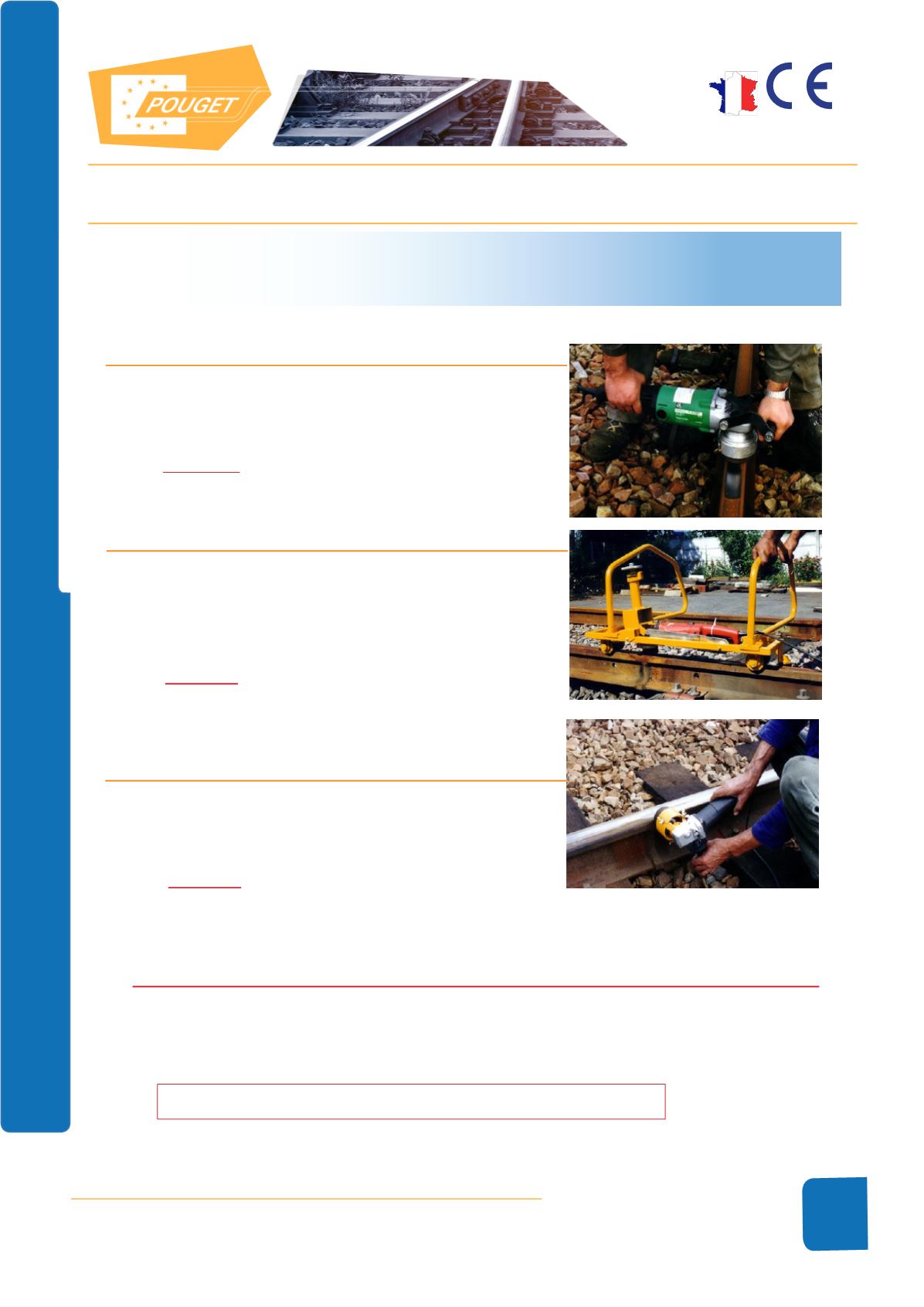

USE :

Finishing Grinding after Welding and Re-loading of rails Switches and Crossings.

(It is forbidden to use these Grinders with the rain)

ADVANTAGES :

Reliable, Strong and Silent.

NP-5

PORTABLE RAIL GRINDER MACHINE

2500 W - 230 V - 50 Hz

Ø 115 mm Cup Grinding Wheel (Ref. 1039-K)

Weight = 6 Kg

NP-17

LIGHTWEIGHT PORTABLE RAIL GRINDER

2600 W - 230 V - 50 Hz

Ø 115 mm Cup Grinding Wheel (Ref. 1039-K)

Centre-to-centre Guide Runners : 750 mm

(all Other Dimensions on request)

Weight = 35 Kg

MPE-10

PORTABLE RAIL GRINDER

1300 W - 230 V - 50Hz

Ø 72 mm Cup Grinding Wheel (Ref. 1039-D)

Weight = 2.3 Kg

OPTIONS

GrindingWheels

- Tech. Spec. NO.

2/2

Portable Generating Sets

- Tech. Spec NO.

24/1

Welding Rules

- Tech. Spec. NO.

2/6

Thermic Rail Grinders

- Tech. Spec. NO.

5/1

and

6/1

Nota

: Do not use these Rail Grinders with the rain for your SECURITY

MAIN USE

- Finishing Grinding after Aluminothermic Welding.

MAIN USE

connecting at Switches and crossings after re-loading.

: For rail levelling (Rail Corrugation) and

MAIN USE

Joints andWelding Rectification, as well as Switches

and Crossings.

: for Rail Grinding Finition and for

ELECTRIC RAIL GRINDERS

(230 V - 50 Hz)